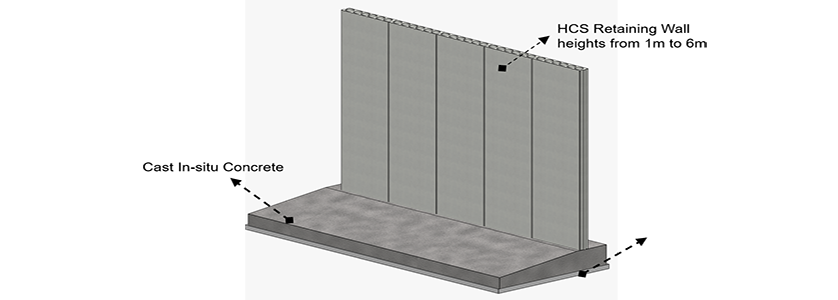

PRECAST CONCRETE RETAINING WALL

A Hollow Core Slab retaining wall is designed and constructed to resist lateral soil pressures when the desired change in ground elevation exceeds the soil’s angle of repose.

TYPICAL CROSS SECTION & CAST IN-SITU CONCRETE

TYPICAL CROSS SECTION OF A HC SLAB 6/200

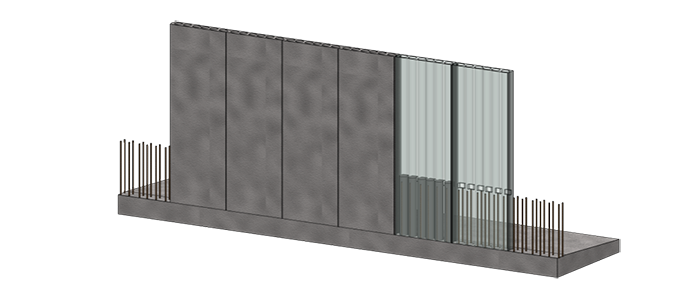

HCS PLACED CAST IN-SITU CONCRETE

RETAINING WALL TYPES

TYPE 1

TYPE 2

BENEFITS

Reduced Site Impact

Precast HCS retaining walls are manufactured off-site and delivered on demand, significantly reducing truck traffic, dust, noise, and debris from formwork associated with cast-in-place products.

Durability

Concrete is strong and durable, offering a sustainable solution that will not rust or burn and has a service life exceeding 100 years.

Better Quality

Manufactured in a controlled plant environment, eliminating site-related errors like temperature changes, poor curing, or inconsistent material quality.

Quick and Easy Installation

Precast retaining walls are cast in the factory, requiring no formwork at the site — they can be directly erected onto the tongue while installing.

Low Material Usage

The presence of longitudinal voids in the HCS cross-section leads to reduced raw material usage, making it cost-effective and efficient.

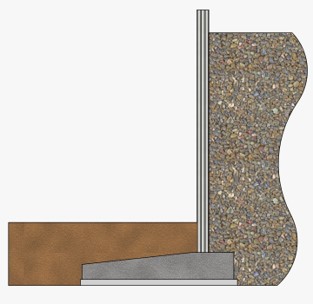

TYPICAL CONNECTION DETAILS

HCS Retaining Wall Engineered for:

- Lateral Pressures

- High Water Table